-

+86-574-62166708

-

-

About us

Factory Area

Advanced Equipment

employees

Monthly Production (10000 meters)

Product Categories

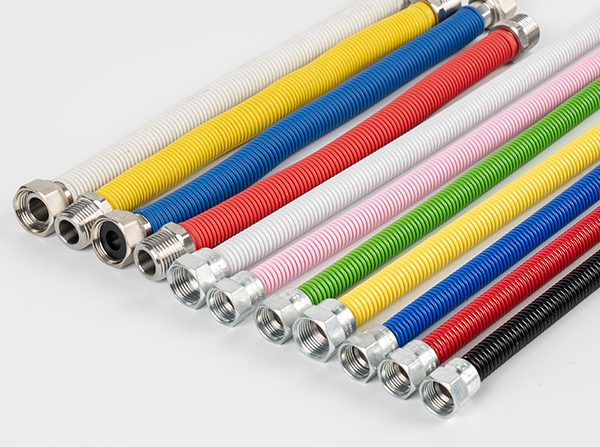

Pipe Diameter: DN12, DN14,DN18, DN21, DN22,Customized/Bespoke

Our advantages

In industries such as industrial manufacturing, chemical engineering, and precision instruments, sealing hoses are key components that ensure the safe transmission of media (gases, liquids) and prevent leakage. Stainless steel bellows, with their unique metallic properties and structural design, have become an ideal choice for scenarios requiring high sealing performance. They can effectively address the limitations of traditional rubber or plastic sealing hoses in terms of temperature resistance, pressure resistance, and corrosion resistance. The following elaborates on specific solutions from multiple dimensions.

Compatibility between Core Performance Advantages and Sealing Requirements

The core demands of sealing hoses are zero leakage, resistance to media, adaptability to environmental changes (temperature and pressure fluctuations), and a certain degree of flexible compensation capability. The characteristics of stainless steel below can precisely meet these requirements:

Excellent Sealing Reliability: Adopting an integrally formed bellows structure made of stainless steel (such as grades 304 and 316), combined with precision-machined connection ends (such as flanges and threaded interfaces), it can achieve tight metal-to-metal sealing. Alternatively, it can further enhance the sealing effect by matching with high-temperature-resistant/corrosion-resistant gaskets (such as PTFE gaskets). It can effectively prevent leakage of gases and liquids (including corrosive media and high-temperature fluids), with a leakage rate as low as 1×10⁻⁹ Pa·m³/s or less.

Wide Temperature Range and Pressure Resistance: It can work stably within a temperature range of -270℃ (ultra-low temperature) to 600℃ (high temperature), far exceeding that of rubber hoses (usually -40℃ to 120℃). At the same time, it can withstand high working pressures (conventional specifications can reach 1.6-10MPa, and specially customized models can reach higher), making it suitable for sealed connections in high-pressure pipeline systems.

Corrosion Resistance and Media Compatibility: 304 stainless steel can resist erosion from water, steam, and weak acids and alkalis, while 316 stainless steel can withstand strongly corrosive media such as seawater, chloride salts, and organic solvents. This avoids sealing failure caused by material aging or erosion by media, making it particularly suitable for corrosive environments in industries such as chemical engineering and pharmaceuticals.

Flexible Compensation and Vibration Resistance: The annular corrugated structure of the bellows endows it with good axial, lateral, and angular compensation capabilities. It can absorb displacements caused by thermal expansion and contraction of pipelines, equipment vibration, or installation misalignment, reducing stress on sealed interfaces and lowering the risk of leakage due to rigid connections.

Structural Stability and Long Service Life: The metal material is not easily aged and has fatigue resistance. It can maintain structural integrity under long-term alternating stresses (such as vibration and pressure fluctuations), with a service life of more than 10 years, far longer than that of rubber hoses (usually 1-3 years).

Typical Application Scenarios

As sealing hoses, stainless steel bellows can widely replace traditional sealing hoses to solve sealing problems in different scenarios:

Sealed Connections in Industrial Pipelines

Used for sealed connections between equipment such as pumps, valves, pressure vessels, and pipelines, especially suitable for pipeline systems transporting high-temperature steam, hot oil, and corrosive liquids, such as the sealing of inlet/outlet pipes of chemical reactors and flexible sealed connections of steam pipelines in power plants.

In pipelines of low-temperature equipment such as LNG and liquid nitrogen, they can be used as sealing hoses to withstand ultra-low temperatures and avoid leakage caused by low-temperature embrittlement.

Sealing of Precision Instruments and Meters

In the gas and liquid path systems of analytical instruments (such as gas chromatographs and mass spectrometers), they can be used as sealing hoses to ensure the clean transmission and zero leakage of carrier gases and samples, ensuring analysis accuracy.

At the connection ends of metering equipment (such as flow meters and pressure gauges), flexible sealing reduces the impact of vibration on metering accuracy and prevents medium leakage.

Sealing Protection of Mechanical Equipment

For pipeline sealing in hydraulic and pneumatic systems, especially for connections of moving parts of equipment (such as oil cylinders and air cylinders), the flexible compensation of bellows can absorb movement displacements, ensuring sealing while avoiding pipeline wear.

For sealing of cooling water pipes and fuel pipes of power equipment such as engines and compressors, they can withstand high temperatures and vibrations during equipment operation, preventing oil and water leakage from causing faults.

Sealing Requirements in Special Environments

In marine engineering, they are used for sealed connections of ship deck pipelines and underwater equipment, resisting seawater corrosion and hull vibration.

In the nuclear industry, sealing hoses for radioactive medium transmission have radiation resistance and high sealing characteristics to ensure safety.

Key Selection Points and Installation Specifications

1. Scientific Selection

Caliber and Length: Select calibers such as DN6-DN300 according to the medium flow requirements. The length should be determined based on the pipeline displacement compensation, with a certain flexible margin reserved (usually 10%-20% longer than the rigid connection length).

Pressure and Temperature: According to the system working pressure (design pressure should be ≥1.5 times the working pressure) and temperature range, select below of corresponding pressure levels and materials (such as 310S stainless steel is preferred for high-temperature working conditions).

Medium Characteristics: For corrosive media, select 304, 316, or Hastelloy materials according to the medium composition (such as chloride ion concentration). If necessary, perform inner wall coating (such as PTFE coating) to enhance corrosion resistance.

Connection Method: Select connection forms such as flanges (socket welding, butt welding), threads (NPT, G threads), and quick connectors according to the equipment interface type, ensuring sealing matching with the interface (such as the flange sealing surface should be compatible with the gasket material).

2. Installation Specifications

Avoid Over-bending and Twisting: During installation, the bending radius must not be less than the bending radius specified by the product (usually 3-6 times the pipe diameter). Twisting of the bellows is strictly prohibited to prevent damage to the corrugated structure, which may affect sealing and service life.

Fixing and Guiding: For long-distance installation, fixed supports should be set at both ends of the bellows, and guide supports should be added in the middle to avoid displacement of the bellows caused by pipeline self-weight or medium impact, ensuring uniform stress on the sealed interface.

Sealing Surface Treatment: Before connection, clean oil stains and burrs on flange surfaces and threaded interfaces. For flange connections, tighten bolts evenly (tighten diagonally step by step). For threaded connections, apply sealant (such as PTFE tape) to enhance sealing performance.

Leakage Test: After installation, a pressure test (pneumatic or hydraulic) must be carried out. The test pressure is 1.25 times the working pressure, and the pressure is maintained for 30 minutes without a pressure drop or leakage to be qualified.

Application Benefits

Reduced Leakage Risk: Compared with traditional rubber sealing hoses, the leakage rate of stainless steel bellows is reduced by more than 90%, reducing safety accidents caused by medium leakage (such as fires caused by leakage of flammable and explosive media, and personal injury caused by leakage of corrosive media).

Reduced Maintenance Costs: The long service life characteristic extends the replacement cycle by 3-5 times. At the same time, corrosion resistance and temperature resistance reduce the maintenance frequency caused by material aging, and the comprehensive maintenance cost can be saved by more than 50%.

Expanded Application Boundaries: It can work stably in environments (high temperature, high pressure, strong corrosion) that traditional sealing hoses cannot adapt to, providing reliable sealing solutions for special working conditions.

Improved System Stability: The flexible compensation capability reduces the impact of pipeline stress on equipment interfaces, protects precision equipment such as pumps and valves, and extends their service life.

Summary

As sealing hoses, stainless steel bellows achieve comprehensive benefits of "high sealing, resistance, long service life, and easy installation" through the inherent advantages of metal materials and the flexible design of the corrugated structure. They are an ideal choice for upgrading and replacing traditional hoses in the industrial sealing field, especially in scenarios with strict requirements on sealing performance and environmental adaptability, providing a solid guarantee for the safe and stable operation of the system.

In gas transmission systems, the safety, sealing performance, and stability of pipelines are directly related to the normal operation of the system and personnel safety. Whether it is industrial gases (such as oxygen, nitrogen, hydrogen), fuel gases (natural gas, liquefied petroleum gas), or special gases (such as corrosive gases, high-purity gases), the requirements for transmission pipelines are extremely strict. Stainless steel bellows, with their unique material and structural advantages, can effectively solve problems such as leakage, corrosion, and vibration impact faced by traditional pipelines in gas transmission, making them an ideal choice for gas systems. The following elaborates on specific solutions from multiple dimensions.

Precise Matching of Core Performance Advantages with Gas System Requirements

The core requirements of gas systems for pipelines are absolute sealing, resistance to gas corrosion, resistance to vibration and impact, adaptability to pressure fluctuations, and cleanliness control. The characteristics of stainless steel below can perfectly meet these requirements:

Extreme Sealing Performance: Adopting integrally formed 304, 316, and other stainless steel materials, the bellows and connecting ends (such as threads, flanges) achieve tight cooperation through precision machining, which can realize metal-to-metal hard sealing or be matched with special seals (such as copper gaskets, PTFE gaskets) to ensure zero gas leakage. For high-pressure gas systems (with working pressure up to 10MPa or more), its sealing reliability is far to rubber hoses or ordinary metal pipelines, and the leakage rate can be controlled below 1×10¹⁰ Pa·m³/s.

Excellent Gas Corrosion Resistance: 304 stainless steel can withstand long-term erosion by dry gases (such as oxygen, nitrogen) and non-corrosive fuel gases; 316 stainless steel, due to its molybdenum content, can resist corrosion by sulfur-containing fuel gases, chlorine gas, hydrogen fluoride, and other corrosive gases, avoiding the formation of holes or impurity shedding on the inner wall of the pipeline caused by erosion, thus ensuring the purity of gas transmission.

Vibration and Pressure Fluctuation Resistance: The annular corrugated structure of the bellows has good elasticity, which can absorb vibrations and pressure pulses generated by compressor operation and valve opening/closing in the gas system, reduce stress concentration at pipeline interfaces, and lower the risk of loose leakage caused by rigid connections. It is especially suitable for connecting parts between gas compressors, storage tanks, and pipelines.

Cleanliness Adaptability: After electrolytic polishing of the inner wall, the surface roughness Ra can be as low as 0.8μm or less, which is not easy to adsorb impurities or moisture in the gas, and no particles fall off. It meets the transmission requirements of high-purity gases (such as ultra-high purity nitrogen used in the electronics industry, special gases used in semiconductor manufacturing) and avoids gas pollution affecting production quality.

Wide Temperature and Pressure Adaptability: It can work stably in the temperature range of -200℃ to 450℃, adapting to the vaporization transmission of low-temperature liquefied gases (such as liquid nitrogen, liquid oxygen) and high-temperature gas systems; the working pressure covers from vacuum to 30MPa, which can not only meet the needs of low-pressure fuel gas pipelines (below 0.1MPa) but also be used in high-pressure industrial gas transmission systems.

Typical Application Scenarios

Stainless steel bellows can specifically solve transmission problems in different types of gas systems:

Industrial Gas Transmission Systems

Used for pipeline connection of inert gases such as oxygen, nitrogen, and argon, especially in welding workshops and metal processing fields. The vibration resistance of bellows can reduce the leakage risk at the connection between oxygen cylinders and pipelines.

In hydrogen transmission systems, 316 stainless steel material can avoid hydrogen embrittlement, and with a special sealing structure, it can prevent explosion hazards caused by hydrogen leakage.

For the transmission of corrosive industrial gases (such as chlorine gas, sulfur dioxide), 316L stainless steel bellows are selected to resist corrosion of the pipeline by gases and ensure the long-term safe operation of the system.

Gas Supply Systems

For indoor and outdoor pipeline connection of urban natural gas and liquefied petroleum gas, bellows are used between gas meters, valves, and main pipelines. Their flexible compensation can reduce interface leakage caused by pipeline displacement due to building settlement or temperature changes.

For gas branch pipes in commercial kitchens and industrial kilns, the temperature resistance of bellows can adapt to the high-temperature environment near stoves, and their anti-aging performance avoids cracking and leakage of rubber hoses due to long-term use.

Special Gas and High-Purity Gas Systems

For the transmission of high-purity gases (such as ultra-high purity ammonia, silane) in the semiconductor and photovoltaic industries, bellows with electrolytically polished inner walls can reduce contact pollution between gases and pipelines, ensuring gas purity (reaching 99.9999% or more);

For laboratory gas pipelines (such as carrier gases for gas chromatographs, special gases for spectral analysis), the low adsorption of bellows ensures the stability of gas components and improves the accuracy of experimental data.

Connection of Gas Storage and Processing Equipment

For the connection between gas storage tanks, cylinders, and vaporizers, pressure reducing valves, bellows can absorb vibrations during equipment operation and protect the sealing performance of valve interfaces;

For the connection between the liquid outlet pipe of low-temperature gas (such as liquid nitrogen, liquid argon) storage tanks and vaporizers, bellows can adapt to temperature changes from low temperature to normal temperature, avoiding cracks in pipelines due to thermal expansion and contraction.

Key Selection Points and Installation Specifications

1. Scientific Selection

Material Selection: Determine the material according to gas properties - 304 stainless steel is selected for inert gases and fuel gases; 316/316L stainless steel is selected for corrosive gases and fuel gases in seawater environments; low-carbon stainless steel (such as 316L) with electrolytically polished inner walls is required for high-purity gas systems.

Caliber and Pressure Rating: Select DN6-DN200 calibers according to gas flow. The working pressure must match the system design pressure (for example, 1.6MPa rating is usually selected for gas systems, and a 6.4MPa or higher rating is selected for industrial high-pressure gases).

Connection Method: Threaded connection (with gas-specific sealant) is commonly used in gas systems; flange connection (with O-ring seal) is mostly used in industrial gas systems; VCR face seal joints are selected for high-purity gas systems to ensure zero leakage and cleanliness.

Length and Compensation Amount: Determine the length according to pipeline displacement requirements, and reserve axial or lateral compensation allowance (usually the compensation amount does not exceed 10% of the effective length of the bellows) to avoid affecting the seal due to excessive stretching or compression.

2. Installation Specifications

Fire Prohibition and Cleaning Treatment: Before installing the gas system, ensure that there are no impurities in the pipeline to avoid sparks during installation; before installing the high-purity gas system, clean the inner wall of the bellows with absolute ethanol to remove oil stains and particles.

Bending and Fixing: During installation, the bending radius should not be less than the value specified by the product (usually 5-8 times the pipe diameter), and forced twisting is prohibited; fixed brackets are set every 1.5-2 meters in the straight section, and guide brackets are added at both ends of the bending section to prevent deformation caused by the self-weight of the pipeline.

Sealing Surface Protection: Before connection, check the flatness of flange faces and threaded interfaces, and remove burrs and scratches; apply gas-specific sealant corresponding to the gas during threaded connection (such as PTFE sealing tape for gas), and select gaskets compatible with the gas for flange connection (such as oil-resistant rubber gaskets for gas, PTFE gaskets for corrosive gases).

Leakage Detection: After installation, leakage testing must be carried out - soap water is applied to interfaces for bubble detection in gas systems; helium mass spectrometers are used in industrial gas and high-purity gas systems to ensure that the leakage rate meets system requirements (such as the leakage rate of high-purity gas systems ≤1×10⁻¹¹ Pa·m³/s).

Application Benefits

Improve System Safety: Compared with traditional galvanized steel pipes or rubber hoses, the leakage risk of stainless steel bellows is reduced by more than 95%, especially in gas systems with flammable and explosive gases such as fuel gas and hydrogen, which can significantly reduce potential safety accidents.

Prolong Service Life: Stainless steel materials are anti-aging and corrosion-resistant, with a service life of more than 20 years, far exceeding that of rubber hoses (1-3 years) and ordinary steel pipes (8-10 years), reducing replacement frequency and maintenance costs.

Ensure Gas Purity and Quality: In high-purity gas systems, it can avoid product scrapping caused by pipeline pollution (such as defects in semiconductor chips caused by impure gases) and reduce production losses.

Adapt to Complex Working Conditions: The flexible compensation capability solves the impact of building settlement, equipment vibration, and temperature changes on pipelines, reduces shutdown maintenance caused by pipeline damage, and improves the stability of system operation.

Summary

Through material adaptation, structural optimization, and precision machining, stainless steel bellows achieve comprehensive performance of "safe sealing, corrosion resistance and durability, and clean transmission" in gas systems. Whether it is conventional industrial gases, civil fuel gases, or high-demand special gas systems, they can provide reliable transmission solutions, providing a solid guarantee for the safe and stable operation of gas systems.

Heating systems (including civil heating, industrial heating, new energy heating, etc.) have core requirements for pipelines, such as high temperature resistance, thermal fatigue resistance, reliable sealing, adaptability to thermal expansion and contraction, and medium compatibility. Traditional metal pipes (such as galvanized steel pipes) are prone to cracking due to thermal stress, while plastic pipes are limited by the upper temperature limit. However, stainless steel bellows, with their unique material and structural design, can effectively solve these problems and become an ideal pipeline solution for heating systems. The following elaborates on specific application solutions from multiple dimensions.

In-depth Adaptation of Core Performance Advantages to Heating System Requirements

The operating environment of heating systems is characterized by large temperature fluctuations (-10℃ to 300℃), diverse media (hot water, steam, heat-conducting oil, etc.), and the existence of thermal stress and vibration. The performance of stainless steel bellows can accurately meet these requirements:

Excellent High Temperature Resistance and Thermal Stability: 304 stainless steel can withstand medium-temperature environments below 200℃ (such as civil hot water heating), 316 stainless steel can adapt to high-temperature scenarios of 200-400℃ (such as industrial steam pipelines), and special grades (such as 310S) can even work stably in open-fire heating systems above 600℃. The material will not age or have strength attenuation due to long-term high temperatures.

Thermal Fatigue Resistance and Expansion Compensation Capability: The annular corrugated structure of the bellows endows it with good axial extensibility. During the cycle of heating system startup (temperature rise) and shutdown (temperature drop), it can absorb the length change of the pipeline caused by thermal expansion and contraction (the compensation amount can reach 5%-10% of its own length), reducing interface loosening or pipeline cracking caused by rigid connections. It is especially suitable for connecting boilers, heat exchangers and other equipment with main pipelines.

Medium Compatibility and Corrosion Resistance: It has tolerance to common heating media such as hot water, steam, and heat-conducting oil. 304 stainless steel can resist scaling of calcium and magnesium ions in water and oxygen corrosion. 316 stainless steel can withstand erosion from sulfur-containing steam and weakly acidic heat-conducting media, avoiding medium leakage caused by corrosion and perforation of the inner wall of the pipeline.

Sealing Reliability and Pressure-bearing Capacity: Through precision-machined flange, thread and other connection structures, combined with high-temperature resistant sealing gaskets (such as graphite gaskets, metal-clad gaskets), zero-leakage sealing under long-term high temperatures can be achieved. The working pressure can reach 1.6-10MPa, meeting the pressure requirements of low-pressure civil heating (below 0.6MPa) and high-pressure industrial steam systems (above 4.0MPa).

Heat Conduction Efficiency and Energy Saving: The thermal conductivity of stainless steel (about 16-21 W/(m·K)) is higher than that of plastic pipes, and the annular structure of the bellows can increase the contact area between the medium and the pipeline, accelerating heat transfer. At the same time, the outer wall of the pipeline can be conveniently equipped with an insulation layer to reduce heat loss and improve the energy-saving performance of the system.

Typical Application Scenarios

Stainless steel bellows can specifically solve the application pain points of traditional pipelines in different types of heating systems:

Civil Heating and Hot Water Systems

Connecting branch pipes between radiators and main pipes: Using the flexibility of bellows, they can easily bypass obstacles such as walls and furniture, reduce the use of elbows, and lower water flow resistance; at the same time, they absorb pipeline expansion and contraction during heating and non-heating seasons to avoid interface leakage.

Connection between wall-hung boilers and hot water pipelines: They can withstand the 80-95℃ hot water temperature during the operation of wall-hung boilers, resist thermal fatigue caused by frequent startup and shutdown, and are more durable than rubber hoses (easy to age) and copper pipes (strong rigidity), with a service life of more than 15 years.

Connection of manifolds in low-temperature floor radiant heating (water floor heating): Small-caliber (DN15-DN25) bellows can adapt to the multi-branch layout of floor heating pipes, reduce water flow resistance, and improve heat dissipation uniformity.

Industrial Heating Systems

Connection between boilers and steam pipelines: At the outlet of coal-fired/gas-fired boilers, bellows can absorb the severe thermal expansion during boiler startup, protect valves and pipeline interfaces, and avoid steam leakage (steam temperature is usually 150-300℃, pressure 1.0-4.0MPa).

Heat-conducting oil heating systems: Used for connecting heat-conducting oil furnaces with reactors, dryers and other equipment. 316 stainless steel can withstand long-term erosion of heat-conducting oil (temperature 200-300℃), and its vibration resistance (generated by pump operation) prevents loosening of pipeline joints.

Pipeline connection of electric heating equipment: Such as the inlet and outlet pipelines of electric heating reactors, bellows can adapt to the local high temperature of electric heating elements, and there is no problem of odor emission from plastic pipes.

New Energy Heating Systems

Circulation pipelines of solar thermal collection systems: Connecting solar collectors and hot water storage tanks, 304 stainless steel can resist high temperatures (70-100℃) under direct sunlight and rain corrosion, and the flexible structure adapts to the slight displacement of collectors due to installation angles.

Water circulation pipelines of air-source heat pumps: In the temperature fluctuation range of -10℃ to 55℃, bellows can compensate for the expansion and contraction of pipelines caused by environmental temperature changes, avoiding low-temperature embrittlement or high-temperature deformation of plastic pipes.

Special Heating Scenarios

Steam disinfection pipelines in the food processing industry: The inner wall of stainless steel bellows is smooth and easy to clean, meeting food hygiene standards (such as 3A certification), withstanding 121℃ high-temperature steam disinfection, and having no risk of rust pollution.

Pipeline connection of laboratory heating equipment (such as oil baths, constant temperature tanks): Small-caliber bellows (DN6-DN15) can accurately adapt to precision equipment, and their vibration resistance ensures stable medium transmission during experiments.

Key Selection Points and Installation Specifications

1. Scientific Selection

Material Matching: 304 stainless steel is selected for medium-temperature systems (≤200℃); 316 stainless steel is selected for high-temperature systems (200-400℃) or corrosive media (such as sulfur-containing steam); 310S stainless steel is selected for ultra-high temperature systems (>400℃).

Caliber and Pressure Rating: Select DN10-DN300 calibers according to the flow rate of heating medium (DN15-DN50 is commonly used for civil purposes, DN50-DN200 for industrial purposes); the working pressure must be ≥1.25 times the system design pressure (for example, if the design pressure of a steam system is 1.6MPa, select bellows with a rating of ≥2.0MPa).

Connection Method: Threaded connection (with high-temperature resistant raw material tape) is commonly used in civil systems; flange connection (with metal wound gaskets) is mostly used in industrial systems; ferrule joints can be selected for precision equipment connection (to ensure cleanability without dead corners).

Expansion Compensation Amount: Calculate the thermal expansion amount according to the pipeline length and temperature difference (formula: ΔL=α×L×ΔT, where α is the linear expansion coefficient of stainless steel), ensuring that the compensation amount of the bellows is ≥ the calculated value to avoid excessive stretching or compression.

2. Installation Specifications

Pretreatment and Cleaning: Before installation, remove oxide scale and oil stains in the pipeline. High-temperature systems need to be degreased (such as cleaning with trichloroethylene); when connecting with food and pharmaceutical equipment, bellows with electrolytically polished inner walls must be selected to avoid microbial growth.

Bending and Fixing: The bending radius is ≥ the radius specified by the product (usually 6-10 times the pipe diameter). It is forbidden to apply excessive force during cold bending to cause corrugation deformation; sliding supports are set every 2-3 meters in the straight section (allowing axial expansion), and fixed supports are set at both ends of the compensation section to limit lateral displacement.

Sealing and Insulation: When flange connection is used, tighten the bolts evenly (step by step diagonally) to avoid seal failure caused by eccentric load; high-temperature pipelines need to be wrapped with insulation layers (such as rock wool, aluminum silicate) outside the bellows, but expansion space must be reserved to prevent the insulation layer from hindering the compensation of the bellows.

Trial Operation and Testing: After installation, conduct a water pressure test (the test pressure is 1.5 times the working pressure, and the pressure is maintained for 30 minutes without leakage); high-temperature systems need to conduct hot commissioning to monitor whether the bellows expand and contract smoothly and whether there is leakage at the interface.

Application Benefits

Prolong System Service Life: The thermal fatigue resistance of stainless steel bellows can extend the trouble-free operation cycle of the heating system to more than 10 years, far exceeding that of galvanized steel pipes (5-8 years) and plastic pipes (3-5 years), reducing replacement costs.

Reduce Maintenance Costs: Corrosion resistance and high-temperature resistance reduce shutdown maintenance caused by pipeline corrosion and rupture, and annual maintenance costs can be reduced by 40%-60%; especially in industrial heating systems, production losses caused by medium leakage can be avoided.

Improve Operational Safety: Zero-leakage sealing and anti-thermal stress design reduce the risk of scalds and fires caused by leakage of high-temperature media (such as steam and heat-conducting oil), and can reduce property losses caused by household water leakage in civil heating.

Enhance System Adaptability: The flexible compensation capability makes pipeline installation not limited by building structures (such as walls and floors), especially suitable for the transformation of heating systems in old buildings, reducing wall excavation and structural damage.

Summary

Through the dual advantages of material and structure, stainless steel bellows achieve comprehensive performance of "high temperature resistance, anti-expansion, stable sealing, and long service life" in heating systems. Whether it is the comfort requirements of civil heating or the harsh working conditions of industrial heating, they can provide reliable pipeline solutions, laying a solid foundation for the efficient and safe operation of heating systems.

Stoves (including household gas stoves, commercial kitchen stoves, industrial furnaces, etc.) have strict requirements for connecting pipelines, such as safety and leakproofness, high temperature resistance, corrosion resistance to gas and its impurities, flexibility for installation, and long-term reliability. Traditional rubber hoses are prone to aging, cracking, and rat bites, while rigid metal pipes lack flexibility, making installation difficult. Stainless steel bellows, with their unique material properties and structural design, can effectively address these pain points and become an ideal choice for stove connection pipelines. The following elaborates on specific application solutions from multiple dimensions.

Core Performance Advantages and Precise Matching with Stove Requirements

The operating environment of stoves is characterized by high ambient temperature (up to 150℃ near the burner), frequent ignition and flameout, contact with gas (natural gas, liquefied petroleum gas) and condensate water, and the need for safe and flexible connection. The performance of stainless steel bellows can accurately meet these requirements:

Excellent Safety and Leakproofness: Made of high-quality 304 stainless steel, the bellows has a one-piece structure with no joints in the middle, reducing the risk of leakage. The connection ends (threaded or quick-connect) are precision machined and equipped with special sealing rings (such as nitrile rubber or EPDM) that are compatible with gas, ensuring reliable sealing even under long-term use and temperature changes.

High Temperature Resistance and Fire Resistance: It can withstand high temperatures up to 300℃, which is far higher than the ambient temperature near the stove burner. Even if it comes into contact with open flames accidentally, it will not melt or burn, avoiding fire accidents caused by hose burning, which is much safer than rubber hoses.

Corrosion Resistance and Gas Compatibility: It is resistant to corrosion from gas components (such as sulfides in natural gas) and condensate water generated during gas combustion, avoiding rust and perforation. It is compatible with various gases, including natural gas, liquefied petroleum gas, and artificial gas, without material degradation or reaction.

Flexibility and Installation Adaptability: The bellows can be bent freely (minimum bending radius is 3-5 times the pipe diameter), adapting to the complex spatial layout of kitchens. It can easily connect the gas source (gas meter, gas cylinder) to the stove, reducing the need for elbows and adapters, and simplifying the installation process.

Anti-aging and Long Service Life: Unlike rubber hoses that are prone to aging, hardening, and cracking due to temperature, ultraviolet rays, and oil fumes, stainless steel bellows have anti-aging performance. Its service life can reach 10-15 years, far exceeding the 18-month to 2-year service life of rubber hoses, reducing the frequency of replacement.

Typical Application Scenarios

Stainless steel bellows can be applied to various types of stoves to solve connection problems:

Household Gas Stoves

Connection between Gas Meter and Stove: In home kitchens, it is used to connect the gas meter or gas valve to the stove. Its flexibility allows it to be routed through cabinets and around obstacles, avoiding the safety hazards of rubber hoses being crushed or kinked.

Built-in Stove Connection: For built-in stoves installed in cabinets, the bellows can be bent into a suitable shape to fit the narrow space, ensuring good ventilation and avoiding gas accumulation.

Commercial Kitchen Stoves

Large-scale Stoves in Restaurants and Canteens: Used to connect commercial stoves (such as wok stoves, steam stoves) with the gas pipeline. It can withstand the high-temperature environment of commercial kitchens and the vibration of stoves during use, ensuring a stable gas supply.

Gas Fryers and Ovens: The high temperature resistance of the bellows makes it suitable for connecting gas fryers and ovens that generate high heat during operation, avoiding pipeline damage caused by high temperature.

Industrial Furnaces

Industrial Heating Furnaces and Annealing Furnaces: Used for gas supply pipelines of industrial furnaces. It can adapt to the high temperature around the furnace and the pressure fluctuations of industrial gas, ensuring a safe and continuous gas supply.

Key Selection Points and Installation Specifications

1. Scientific Selection

Material and Caliber: 304 stainless steel is sufficient for household and general commercial stoves; for industrial environments with more severe conditions, 316 stainless steel can be selected for better corrosion resistance. The caliber is selected according to the gas consumption of the stove, usually DN10 (3/8 inch) for household stoves and DN15 (1/2 inch) or larger for commercial stoves.

Length and Pressure Rating: The length should be appropriate, generally not exceeding 2 meters for household use to avoid excessive pipeline resistance. The pressure rating should be ≥ 1.6MPa to meet the gas supply pressure requirements (usually 2-3kPa for household, up to 5kPa for commercial).

Connection Type: Household stoves commonly use threaded connections with gas-specific nuts; commercial stoves can use flange connections or quick-connect joints for convenient disassembly and maintenance.

2. Installation Specifications

Avoid Over-bending and Twisting: During installation, the bending radius should not be less than the specified value to prevent damage to the bellows structure and affect its service life and safety. Do not twist the pipeline to avoid loosening the seal.

Firm Fixing: The bellows should be fixed with special clips at intervals (every 50-80cm) to avoid shaking and friction with other objects, which may cause wear. Do not pull the pipeline forcibly during installation.

The pipeline should be kept at a distance of at least 30cm from the stove burner and other high-temperature components. If it is unavoidable, heat insulation measures (such as heat insulation sleeves) should be taken.

Leakage Detection: After installation, a leak test must be carried out. Apply soapy water to the connection parts; if no bubbles are generated, it indicates no leakage. Do not use an open flame for leak detection to avoid danger.

Regular Inspection and Replacement: Check the bellows regularly for signs of damage, corrosion, or loose connections. It should be replaced in time when it reaches the service life or is damaged, and must be replaced by professional personnel.

Application Benefits

Improve Safety: The use of stainless steel bellows reduces the risk of gas leakage caused by aging, rat bites, and high temperature of rubber hoses, effectively preventing gas explosions and fire accidents, and ensuring the safety of life and property.

Reduce Maintenance Costs: Its long service life reduces the frequency of replacement compared with rubber hoses, saving the cost and trouble of frequent replacement. At the same time, its corrosion resistance reduces the maintenance work caused by pipeline damage.

Simplify Installation: The flexibility of the bellows makes the installation of stove pipelines more convenient, adapting to various kitchen layouts, reducing the difficulty of construction, and improving installation efficiency.

Comply with Safety Standards: It meets the requirements of national safety standards for gas appliances (such as GB 29993-2013 "Stainless Steel Corrugated Hoses for Gas"), and can pass the inspection of relevant departments, ensuring compliance with regulations.

Summary

Stainless steel bellows, with its safety, high temperature resistance, corrosion resistance, flexibility, and long service life, provides a reliable connection solution for various stoves. It effectively solves the safety hazards and installation difficulties of traditional connection pipelines, and is an ideal choice for improving the safety and reliability of stove gas supply systems.

Sanitary systems (including medical hygiene, food and beverage processing, pharmaceutical production, and public sanitation facilities) have extremely strict requirements for pipelines, such as high cleanliness, corrosion resistance, easy cleaning, non-toxicity, and compliance with hygiene standards. Traditional pipelines (such as plastic pipes or ordinary metal pipes) often have problems such as easy contamination, difficult cleaning, or corrosion in harsh environments. Stainless steel bellows, with their material properties and structural design, can perfectly meet the special needs of sanitary systems and become a reliable pipeline solution. The following elaborates on specific application solutions from multiple dimensions.

Precise Matching of Core Performance Advantages with Sanitary System Requirements

Sanitary systems operate in environments characterized by frequent cleaning (CIP/SIP), contact with various cleaning agents (acids, alkalis), high temperature disinfection, and strict prevention of microbial growth. The performance of stainless steel bellows can accurately meet these requirements:

Excellent Corrosion Resistance: Made of 304 or 316L stainless steel, it can resist corrosion from various cleaning agents (such as peracetic acid, sodium hydroxide) and disinfectants used in sanitary systems. 316L stainless steel, with its higher molybdenum content, has stronger resistance to chloride ion corrosion, making it suitable for environments with high salt content (such as seafood processing) or frequent use of chlorine-containing disinfectants.

High Cleanliness and Non-toxicity: The inner wall of the bellows is smooth (Ra ≤ 0.8μm) after electrolytic polishing, without dead corners or pores, which can prevent the adhesion and reproduction of microorganisms (bacteria, fungi, etc.). It does not release harmful substances and complies with international hygiene standards such as FDA, 3A, and USP Class VI, ensuring that the medium (water, food, medicine) is not contaminated.

Temperature Resistance and Adaptability to Disinfection: It can withstand high-temperature disinfection processes (such as 121℃ saturated steam sterilization for 30 minutes) and low-temperature environments (down to -40℃), adapting to the frequent temperature changes in sanitary systems during cleaning and operation. It will not deform or aging due to temperature fluctuations.

Smooth Inner Wall and Low Pollution Risk: The ultra-smooth inner surface reduces the retention of media residues, making it easy to clean during CIP (Clean-in-Place) processes. Compared with rough-surfaced pipes, it can reduce the frequency of cleaning and the use of cleaning agents, saving costs and reducing environmental impact.

Mechanical Strength and Long Service Life: It has high tensile strength (≥520MPa) and impact resistance, can withstand the pressure fluctuations in sanitary pipelines (usually 0.1-1.0MPa), and is not easy to be damaged during installation or use. Its service life can reach more than 10 years, far exceeding that of plastic pipes (3-5 years), reducing the frequency of replacement and maintenance.

Typical Application Scenarios

Stainless steel bellows can solve the application pain points of traditional pipelines in different types of sanitary systems:

Medical and Healthcare Sanitary Systems

Medical Water Supply Pipelines: Used for transporting purified water, sterile water, and dialysis water in hospitals. The smooth inner wall and corrosion resistance of the bellows prevent secondary pollution of water quality, ensuring the safety of medical water use.

Disinfection Pipeline Connections: Connecting autoclaves, sterilizers, and other equipment, it can withstand high-temperature and high-pressure steam disinfection, ensuring the tightness of the pipeline during the disinfection process.

Wastewater Discharge in Operating Rooms: Used for the discharge of contaminated wastewater in operating rooms, 316L stainless steel bellows can resist corrosion from blood, drugs, and disinfectants in the wastewater.

Food and Beverage Processing Sanitary Systems

Raw Material Transportation Pipelines: In dairy, beverage, and brewing production lines, it is used to transport raw materials (milk, juice, syrup, etc.). The non-toxic and smooth inner wall avoids material residue and bacterial growth, meeting food-grade hygiene requirements.

Cleaning Pipeline Systems: Connecting CIP cleaning equipment and production equipment, it can withstand the erosion of high-temperature cleaning fluids (80-95℃) and chemical cleaning agents, ensuring effective cleaning without pipeline damage.

Steam Sterilization Pipelines in Food Factories: Used for steam transportation in food sterilization processes, it adapts to frequent high-temperature steam impact and maintains stable performance.

Pharmaceutical Production Sanitary Systems

API (Active Pharmaceutical Ingredient) Transportation: In pharmaceutical workshops, it is used to transport APIs and intermediate products. The bellows meets GMP standards, with no adsorption or leaching, ensuring the purity of pharmaceuticals.

Purified Water and Water for Injection Pipelines: Connecting water treatment equipment and filling lines, it can withstand high-temperature circulation of purified water and meet the strict hygiene requirements of water for injection systems.

Public Sanitary Facilities

Water Supply Pipelines in Public Bathrooms: Used in high-traffic public places such as gyms and swimming pools, it resists corrosion from chlorine-containing water and has good pressure resistance to adapt to frequent water use.

Wastewater Treatment Pipelines in Public Areas: For the transportation of domestic wastewater in stations, airports, etc., it resists corrosion from organic matter in wastewater and is not easy to block due to its smooth inner wall.

Key Selection Points and Installation Specifications

1. Scientific Selection

Material Selection: 304 stainless steel is suitable for general sanitary environments (such as public bathrooms); 316L stainless steel is preferred for harsh environments with strong corrosion (such as pharmaceutical production, seafood processing) or frequent use of strong disinfectants.

Caliber and Pressure Rating: Select calibers (DN15-DN100) according to the flow requirements of the sanitary system. For example, small calibers (DN15-DN32) are used for medical water supply, and medium calibers (DN40-DN80) are used for food processing pipelines. The pressure rating should be ≥ 1.5 times the working pressure (usually 1.0-1.6MPa).

Surface Treatment: The inner wall must undergo electrolytic polishing (Ra ≤ 0.8μm) to ensure smoothness and easy cleaning; the outer wall can be polished or passivated to enhance corrosion resistance.

Connection Methods: Sanitary clamp connections (Tri-Clamp) are commonly used, which are easy to disassemble and clean, suitable for systems requiring frequent maintenance; flanged connections with sanitary gaskets (such as EPDM, PTFE) are used for high-pressure pipelines to ensure sealing and hygiene.

2. Installation Specifications

Cleanliness Control: Before installation, the bellows must be cleaned (using pure water or alcohol) to remove oil, rust, and other impurities. For pharmaceutical and food systems, degreasing and passivation treatments are required to meet aseptic requirements.

Avoid Dead Corners: During installation, minimize the use of elbows and tees. If necessary, use large-radius sanitary elbows to avoid dead corners where dirt accumulates. The bending radius of the bellows should be ≥ 5 times the pipe diameter to prevent deformation affecting cleanliness.

Sealing Requirements: The sealing gaskets must be food-grade or medical-grade (such as EPDM for high temperature, PTFE for acid and alkali resistance) and be replaced regularly to prevent bacterial growth due to gasket aging.

Sterilization and Testing: After installation, conduct pressure testing (using pure water or compressed air) to ensure no leakage. For aseptic systems, perform SIP (Sterilization-in-Place) sterilization to verify that the pipeline meets microbial limits (≤ 10 CFU/100mL).

Application Benefits

Guarantee Hygiene Safety: The smooth inner wall and corrosion resistance of stainless steel bellows prevent microbial contamination and medium deterioration, reducing product scrapping in food and pharmaceutical production and avoiding medical accidents in healthcare systems.

Reduce Maintenance Costs: The long service life and easy cleaning characteristics reduce the frequency of pipeline replacement and cleaning. Compared with plastic pipes, the annual maintenance cost can be reduced by 40%-60%.

Comply with Regulatory Requirements: Meet international hygiene standards (FDA, 3A, GMP, etc.) and national regulatory requirements for sanitary systems, avoiding penalties or production suspension due to non-compliance.

Improve Production Efficiency: The reliable performance ensures stable operation of sanitary systems, reducing downtime caused by pipeline failures. The easy disassembly of sanitary connections speeds up maintenance and cleaning processes.

Summary

Stainless steel bellows, with their corrosion resistance, high cleanliness, and compliance with hygiene standards, provide a "safe, reliable, and efficient" pipeline solution for sanitary systems. Whether in medical, food, pharmaceutical, or public health fields, they can meet the strict hygiene requirements and complex working conditions, laying a solid foundation for the safe operation of sanitary systems.

Air conditioning and ventilation systems (including central air conditioning, commercial ventilation, clean air conditioning, etc.) have core requirements for pipelines, such as smooth air/medium transmission, vibration resistance and noise reduction, temperature and moisture resistance, flexible installation, and long-term stability. Traditional air ducts (such as galvanized steel sheet ducts) have problems such as high rigidity and large vibration noise, while plastic pipes are limited by temperature resistance and strength. Stainless steel bellows, with their unique material and structural advantages, can effectively adapt to the complex working conditions of air conditioning and ventilation systems, becoming an ideal choice to optimize pipeline performance. The following elaborates on specific application solutions from multiple dimensions.

Precise Matching of Core Performance Advantages with System Requirements

The operating environment of air conditioning and ventilation systems is characterized by temperature fluctuations (-10℃ to 80℃), high air humidity, frequent equipment vibration, and the need to reduce wind resistance and noise. The performance of stainless steel bellows can accurately meet these requirements:

Excellent Temperature and Moisture Resistance: 304 stainless steel can work stably in the temperature range of -40℃ to 300℃, fully covering the requirements of air conditioning systems for supply air (12-18℃), return air (room temperature) and ventilation systems for exhaust temperature (-10℃ to 60℃); at the same time, stainless steel does not absorb water or mildew, and can resist corrosion in high-humidity environments (such as basements, swimming pool ventilation), avoiding pipeline rust or bacterial growth.

Vibration Resistance and Noise Reduction Capability: The annular corrugated structure of the bellows has good elastic shock absorption performance, which can absorb vibrations generated by the operation of air conditioning units and fans (vibration frequency 10-100Hz), reduce the transmission of vibrations to pipelines and building structures, and reduce noise (compared with rigid air ducts, it can reduce noise by 5-15dB); it is especially suitable for places sensitive to noise such as hospitals and laboratories.

Low Wind Resistance and Airflow Stability: The inner wall of the bellows, after smooth treatment (Ra≤1.6μm), has a wind resistance coefficient (λ) as low as 0.02-0.03, which is much lower than the local resistance of traditional rectangular air ducts; the annular cross-sectional design makes the airflow distribution more uniform, avoids eddy currents, and improves the heat exchange efficiency of air conditioning systems and the ventilation effect of ventilation systems.

Installation Flexibility and Space Adaptability: Bellows can be bent arbitrarily (minimum bending radius is 3-5 times the pipe diameter), and can easily bypass obstacles such as beams, columns, and pipes, reducing the use of elbows, tees and other accessories; for narrow spaces (such as ceiling mezzanines, equipment rooms), their flexible characteristics can simplify the installation process and reduce construction difficulty.

Strength and Service Life Advantages: The tensile strength of stainless steel (≥520MPa) is much higher than that of plastic pipes, with impact resistance, which can withstand positive pressure (≤2000Pa) and negative pressure (≥-500Pa) in the air duct, meeting the requirements of high-pressure air supply systems; the service life can reach more than 20 years, far exceeding the anti-corrosion cycle of galvanized steel sheet air ducts (8-12 years).

Typical Application Scenarios

Stainless steel bellows can specifically solve the application pain points of traditional pipelines in different links of air conditioning and ventilation systems:

Central Air Conditioning Systems

Connection section between air conditioning units and air ducts: At the air outlet of water chillers and air handling units, bellows can absorb the vibration from equipment operation, avoid air duct resonance noise caused by rigid connections; at the same time, compensate for displacement between units and air ducts due to installation errors or temperature changes.

Connection between fan coils and branch pipes: Small-caliber (DN80-DN200) bellows are suitable for supply/return air ducts of fan coils. The flexible structure reduces the transmission of fan vibration, and the smooth inner wall does not accumulate dust, reducing the frequency of cleaning and maintenance of air conditioning systems.

Refrigerant pipeline connection: In the refrigerant (such as R32, R410A) pipelines of multi-split air conditioners, bellows can adapt to temperature changes (-15℃ to 60℃) during refrigerant circulation, and their vibration resistance prevents refrigerant leakage caused by loose interfaces.

Commercial and Industrial Ventilation Systems

Kitchen exhaust pipes: Stainless steel bellows are resistant to oil fume corrosion, and their bendable characteristics adapt to the complex spatial layout of kitchens. Their high-temperature resistance (≤300℃) can cope with the instantaneous high temperature of oil fume, which is safer than plastic pipes.

Industrial workshop ventilation: In dusty and humid workshops (such as food processing, machinery manufacturing), the corrosion resistance of bellows can resist dust erosion and condensation water rust. The flexible design facilitates the connection of ventilation outlets in different areas, improving ventilation efficiency.

Fire smoke exhaust systems: High-temperature stainless steel bellows (such as 316 material) can work continuously at 280℃ for more than 30 minutes, meeting the fire resistance requirements of fire smoke exhaust, and their vibration resistance ensures that the pipes do not fall off in case of fire.

Clean Air Conditioning and Special Ventilation

Ventilation in hospital clean operating rooms: Bellows with electrolytically polished inner walls (Ra≤0.8μm) do not accumulate dust and are easy to disinfect, meeting GMP clean standards, reducing the risk of bacterial growth, and adapting to the high-efficiency filtration ventilation system in operating rooms.

Exhaust from laboratory fume hoods: Bellows can connect fume hoods to main air ducts. The chemical corrosion resistance (316 material) resists erosion from laboratory exhaust gas (such as acid-base gases), and the flexible structure facilitates adjusting the installation position of fume hoods.

Air conditioning and ventilation in data centers: In high-density server rooms, bellows can accurately connect air conditioning outlets and cabinet air ducts, reduce cold air loss, and their vibration resistance reduces the interference of air conditioning fans on server operation.

III. Key Selection Points and Installation Specifications

1. Scientific Selection

Material and Caliber: 304 stainless steel is selected for ordinary air conditioning and ventilation systems; 316 stainless steel is selected for humid and corrosive environments (such as kitchens, laboratories); calibers are selected according to air volume requirements from DN50-DN600 (DN100-DN300 is commonly used for civil purposes, DN300-DN600 for industrial purposes).

Pressure and Temperature Rating: Select the corresponding pressure rating according to the system air pressure (1000Pa rating is selected for conventional air duct systems, 2000Pa rating for high-pressure air supply systems); special bellows with temperature resistance ≥280℃ are required for high-temperature scenarios (such as fire smoke exhaust).

Connection Method: Flange connection is used for connecting with equipment interfaces (equipped with rubber gaskets to enhance sealing and shock absorption); clamp connection can be used for air duct section connection (easy to disassemble and clean); welded connection is recommended for clean systems (to reduce leakage points).

Length and Compensation Amount: Determine the length according to installation distance and vibration displacement requirements, and reserve 5%-10% expansion margin to ensure that the bellows can expand and contract freely during vibration or temperature changes, avoiding excessive stretching.

2. Installation Specifications

Cleaning and Pretreatment: Before installation, remove oil stains and impurities in the bellows. Clean systems need to be cleaned with pure water and dried; for ventilation systems related to food and medicine, oil-free treated bellows must be selected to avoid air pollution.

Bending and Fixing: When bending, control the bending radius ≥ the value specified by the product (such as the bending radius of DN200 bellows ≥600mm), and prohibit sharp bends or twists; set sliding supports every 3-5 meters in the straight section (allowing axial movement), and add shock-absorbing supports near vibration sources to reduce pipeline shaking.

Sealing and Noise Reduction Measures: When flange connection is used, tighten the bolts evenly to ensure that the gasket is fully fitted; between vibrating equipment such as fans and air conditioning units and bellows, rubber shock absorbers can be added to further enhance the noise reduction effect.

Testing and Acceptance: After installation, conduct an air pressure test (the test pressure of positive pressure systems is 1.2 times the design pressure, and the pressure is maintained for 1 hour without leakage); during operation, detect the noise value (which should meet the noise standards of the place, such as hospitals ≤40dB).

Application Benefits

Improve System Comfort: Vibration resistance and noise reduction characteristics make air conditioning and ventilation systems run quieter, especially in residences, hotels and other places, which can significantly improve living experience; low wind resistance design reduces airflow noise, avoiding the "wind howl" of traditional air ducts.

Reduce Maintenance Costs: Stainless steel is corrosion-resistant and moisture-resistant, reducing the frequency of replacement due to pipeline rust and mildew, and annual maintenance costs can be reduced by 30%-50%; the smooth inner wall is not easy to accumulate dust, and the cleaning cycle is extended to 1-2 years (traditional air ducts are 3-6 months).

Enhance System Safety: In fire smoke exhaust systems, high-temperature resistant bellows can ensure the smoothness of smoke exhaust channels in case of fire; impact resistance prevents air ducts from being damaged due to vibration and collision, reducing the risk of air leakage.

Improve Installation Efficiency: The flexible structure reduces the use of accessories and on-site cutting and processing, shortening the installation period by 20%-40%, which is especially suitable for the transformation of air conditioning and ventilation systems in old buildings, reducing damage to the original structure.

Summary

Through the optimization of material and structure, stainless steel bellows achieve comprehensive performance of "low noise and high efficiency, corrosion resistance and durability, and flexible adaptation" in air conditioning and ventilation systems. Whether it is comfortable air conditioning in civil buildings or special ventilation in industrial places, they can provide reliable pipeline solutions, laying a solid foundation for the stable operation and performance improvement of the system.

threel NEWS